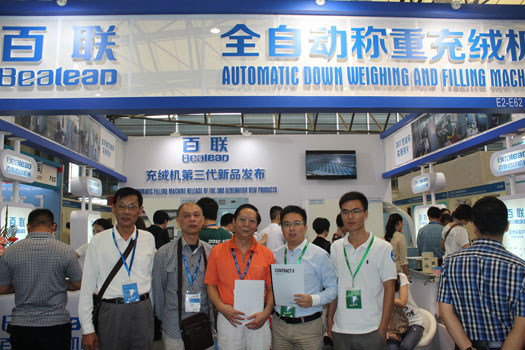

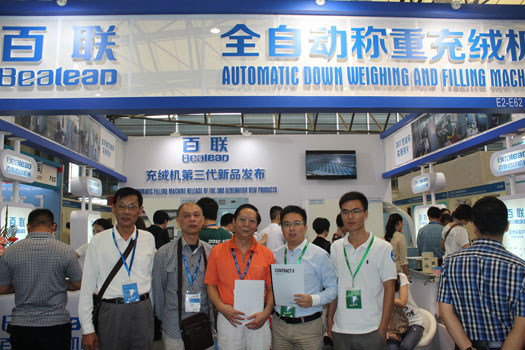

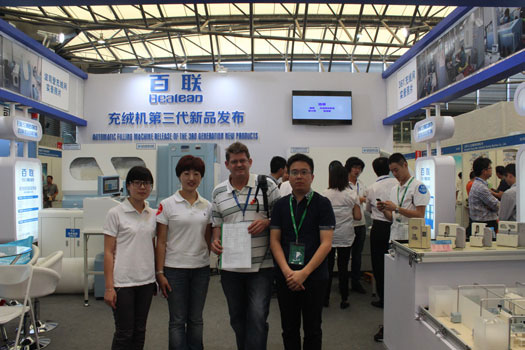

China International Sewing Equipment Exhibition 2013 grandly opened in Shanghai New International Expo Centre on September 25. Exhibited were sewing equipment brands around the globe. Changshu Bealead Automatic Machine Co., Ltd. under Bealead had its exhibition booth in E2 hall. The third generation Bealead fully automatic down-filling machine attracted attention of the whole industry. It is a completely new high-performance fully automatic down-filling machine independently researched, developed and manufactured by Bealead. The new product has greatly improved in performance. At the booth of Bealead, we saw its slogan “We make the best down-filling machine which no longer needs a skilled worker”. What efforts have Bealead made to realize the target? What are the unique advantages of Bealead down-filling machines? For these questions, we interviewed Mr. Wang Xiaofeng, the General Manager of Bealead.

Reporter: It is a very important task for garment enterprises to enhance overall productivity and reduce cost. In order to improve efficiency, it is necessary to replace purely manual work with high-performance automated equipment. What are performances of Bealead fully automatic down-filling machine in this aspect?

GM Wang: Bealead fully automatic down-filling machine fills down twice or three times faster than manual down-filling. The third generation fully automatic down-filling being exhibited on the exhibition is independently operated by two operators and no skill is required. Conservatively estimated, value produced by it will equal the value produced by manual work of 7-8 skilled workers. Non-contact weighing is adopted for the equipment and quantification will be more accurate. It is the most advanced product around the globe. The third generation Bealead down-filling machine (818B) has made many revolutionary breakthroughs in technology, such as 0.01 g grade maximum display precision control, automatic cyclic weighing by three weighing systems, synchronous data transmission and human-machine interaction system based on the Internet of things technology, intelligent automatic increase or reduction during operation and down changing by one key. Optimistically estimated, the equipment cost can be recovered within one year.

Reporter: Down-filling work is very harmful to human health. What improvements have been made to Bealead down-filling machines in environmental protection?

GM Wang: In some manual down-filling workshops, down-filling procedure is very harmful to human health, particularly to human lung, eyes and other organs like that. In case of purely manual down-filling, many workers will suffer from occupational disease, which is incurable and will cause permanent harm to human body. We have taken the lead in proposing the concept of dustless and environment protective down-filling room in China, and independently developed central dust removal system plan. The central dust removal system realizes separation of human and down and can automatically recycle floating down during the down-filling process, which significantly improves working environment in the down-filling room and minimizes the harm caused to employee health by down-filling. The tough problem of down waste is overcome. Raw material is not only saved but also can be recycled. This makes the down-filling workshop meet requirements of international factory audit standards and improves overall image of the factory. On the whole, the down-filling machine has realized modernized dustless environment protection transformation of traditional down-filling room and manual down-filling manner and promoted production upgrading. In terms of dustless environment protection, we have provided the first detailed plan in China, which has been performed by many enterprises with desirable results. We don’t simply provide equipment. We are not purely an equipment manufacturer. We provide the whole management solution. While enhancing productivity, we provide the workers with a safe and healthy working environment, which is worth attention of all enterprises. Enterprises should shoulder such responsibility for health of workers.

Reporter: As a comprehensive enterprise, Bealead also engages in such operations as garment production procedure optimization plan, one piece flow auto line, process and procedure standard analysis and design optimization besides R&D of automatic down-filling machine. What feedback effect do these operations have for automatic down-filling machine?

GM Wang: Bealead is initially specialized in production process optimization, which is related to the layout of factory workshop, arrangement of production and proper arrangement of worker and process, etc. It is the initial positioning that gives Bealead a better understanding of the management demand of manufacturers and prompts its decision on investing in auto equipment for the purpose of assisting the positioning of overall management improvement. Bealead now has 3 companies under it: Bealead Software, Bealead Automatic Machine and Bealead E-commerce-a team of nearly 200 employees, including a development team of 30 odd employees, and an after-sales service team of 20 odd employees, dozens of domestic and overseas contracted market development strategic partners and channels. Meanwhile Bealead has invested large amount of capital in R&D, which helps it in becoming No.1 brand in the industry over a short span of 2-3 years: Best products with greatest stability and high market share. We are very pleased and sincerely thank our partners who explore global market together with us and the customers who support us.

Reporter: Currently, who are the customers of Bealead automatic down-filling machine?

GM Wang: Bosideng, China’s largest world-class down coat group, now uses nearly 60 Bealead down-filing machines. What’s more, there are other domestic large group customers. For example, Bealead down-filing machines are used in the factories of 361° Group in Fujian, and Youngor Group, Shenzhou Group, Lining, Anta, UNIQLO in Ningbo; there are hundreds of Bealead down-filing machines used by customers in various countries of Southeast Asia, Europe and Africa. It is appropriate that Bealead is the leader in down-filling machine technology and the market, so its market share is very high.

Reporter: Bealead has invested a lot in independent R&D, and its products are updated quickly. But there are also down-filling machines manufactured by other companies displayed on the exhibition. In terms of appearance, they look much the same as Bealead’s products. Is there any imitation or plagiarism?

GM Wang: There are indeed several companies imitating our products in China but their product performance lags far behind ours. Besides, there are indeed some illegal factories imitating our products to such extent that the appearance and color of their products are identical to ours, what’s more they deliberately say that the customers of Bealead are theirs. Such illegal publicity method has baffled our customers, leading to some complaints from them. We encourage innovation and desire a market competition environment that is fair and reasonable. But in terms of malicious plagiarism and IPR infringement, we are determined to safeguard our legal rights by resorting to law. We have sued one company that is imitating our products.

Reporter: What is Bealead’s plan for its future development direction?

GM Wang: In the next 5 years, Bealead will continue to position itself at garment industry service and deeply research on how to improve efficiency, lower cost and reduce management and operation difficulties for garment industry. The operations of Bealead’s companies focus on the major theme of improving production efficiency, products quality and management efficiency for the garment industry. We will continue to devote ourselves to improving operation efficiency, lowering operators’ labor intensity and requirements on operator skill by means of auto device and management, thus improving overall efficiency of the factory and lowering its cost. Just like our slogan that is specific to sown-filling machine in our booth “We make the best down-filling machine which no longer needs a skilled worker”. Bealead and its staff will continue to proactively explore and forge ahead with its modest and rigorous attitude.